Global scrap iron magnetic suction machine market size Overview

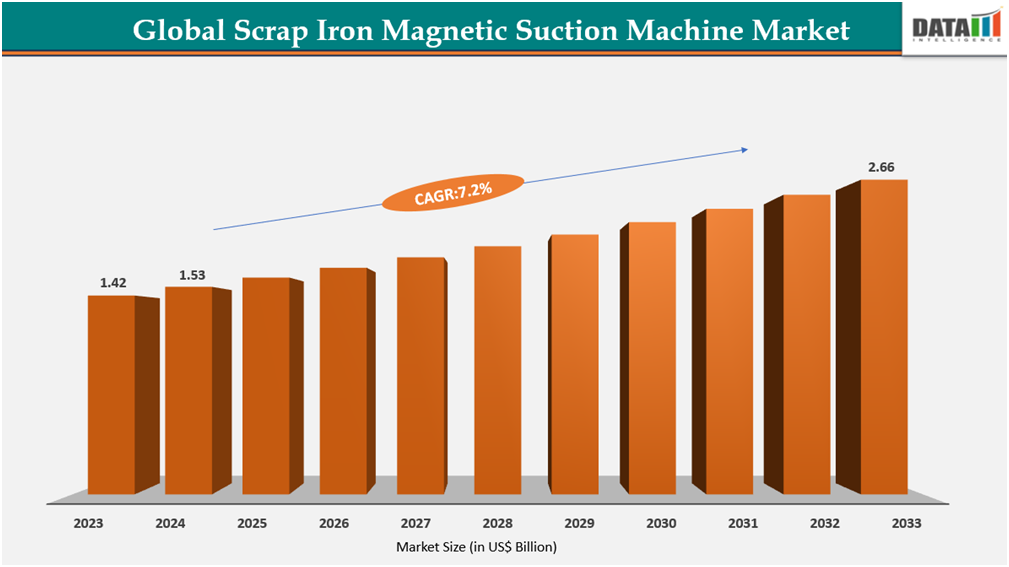

The global scrap iron magnetic suction machine market reached US$1.53 billion in 2024 and is expected to reach US$2.66 billion by 2032, growing at a CAGR of 7.2% during 2025–2032.

This growth is driven by the rising demand for efficient scrap handling across industrial, construction, and recycling sectors, which improves operational efficiency and safety. Strong industrial expansion, government initiatives, and technological innovations in high-capacity magnetic suction systems, automated lifting solutions, and durable industrial magnets are making scrap processing more effective, driving the market toward sustainable and optimized material reuse globally.

Trends and Strategic Insights

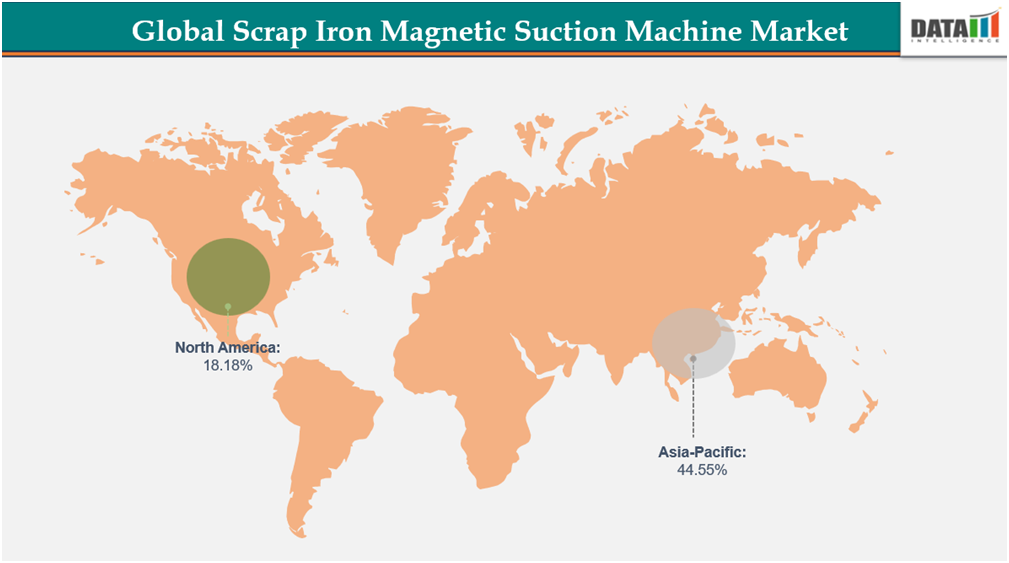

- The Asia-Pacific region leads the global scrap iron magnetic suction machine market, capturing the largest revenue share of 44.55% in 2024.

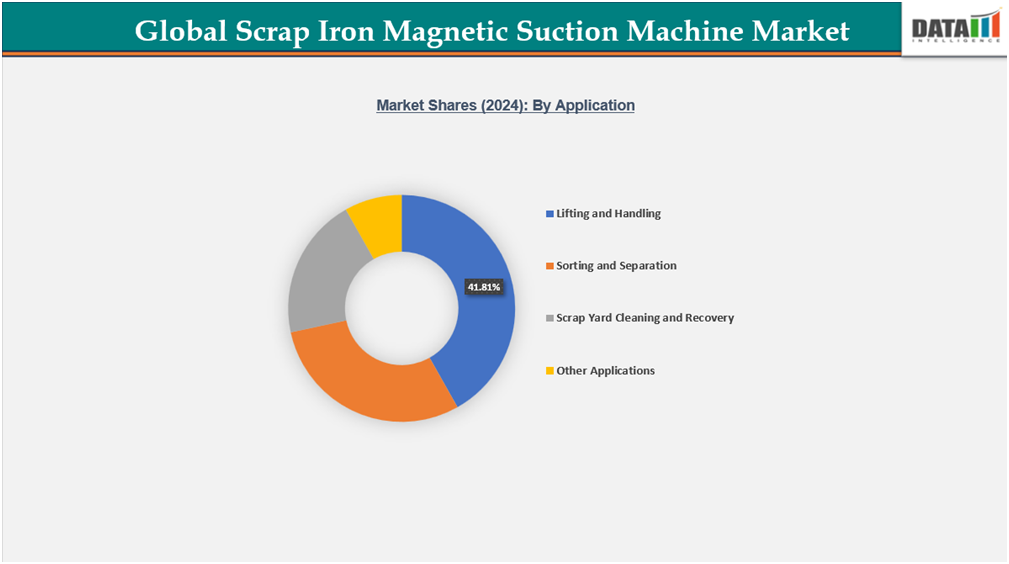

- By application, the lifting and handling sector dominates the global scrap iron magnetic suction machine market, capturing the largest revenue share of 41.81% in 2024.

Market Size and Future Outlook

- 2024 Market Size:US$1.53 billion

- 2032 Projected Market Size:US$2.66 billion

- CAGR (2025–2032):7.2%

- Largest Market: Asia-Pacific

Fastest Growing Market: North America

Source : DataM Intelligence Email : [email protected]

Market Scope

| Metrics | Details |

| By Product Type | Circular Electromagnets, Rectangular Electromagnets, Permanent Magnets, Electro-Permanent Magnets |

| By Application | Lifting and Handling, Sorting and Separation, Scrap Yard Cleaning and Recovery, Other Applications |

| By End Use Industry | Scrap Metal Recycling Yards, Construction and Demolition (C&D) Waste, Recycling Automotive Shredding Facilities, Municipal Solid Waste (MSW) Treatment Plants, Mining and Quarrying, Shipbreaking Yards, Foundries and Steel Mills |

| By Region | North America, South America, Europe, Asia-Pacific, Middle East and Africa |

| Report Insights Covered | Competitive Landscape Analysis, Company Profile Analysis, Market Size, Share, Growth |

Market Dynamics

Increasing demand for efficient scrap handling in industrial sectors

The industrial and recycling sector is a major driver of the scrap iron magnetic suction machine market, as manufacturers and recyclers focus on improving operational efficiency, reducing labor costs, and enhancing safety. Growing industrialization, expansion in automotive, construction, and steel sectors, and rising volumes of scrap metal are fueling demand for advanced magnetic suction solutions.

Companies are introducing innovative and high-capacity machines. For example, in 2024–2025, leading firms such as Siemens, Eriez Manufacturing, and Goudsmit Magnetics expanded their portfolios with automated magnetic suction systems, high-strength lifting magnets, and energy-efficient handling equipment, improving throughput and reliability in scrap operations.

As industrialization and recycling infrastructure continue to expand, particularly in Asia-Pacific, North America, and Europe, such technological advancements are expected to propel investments, optimize scrap handling operations, and accelerate adoption of magnetic suction solutions across industries.

Segmentation Analysis

The global scrap iron magnetic suction machine market is segmented based on product type, application, end use industry and region

Expansion in automotive, construction, and recycling sectors fuels demand

The industrial recycling and manufacturing sector is a major driver of the scrap iron magnetic suction machine market, fueled by the growing need for efficient scrap handling, labor reduction, and operational safety. Machines such as high-capacity magnetic lifters, automated suction systems, and industrial magnets are essential for moving and sorting scrap metal efficiently, offering durability, precision, and scalability.

Global investments in industrial automation and recycling infrastructure are increasing, with significant contributions from governments, private recyclers, and manufacturing companies. Countries like China, the USA, and India are leading in industrial expansion and scrap metal processing, reinforcing the sector’s pivotal role in supporting sustainable recycling, resource optimization, and cost-efficient operations. These investments are crucial for enhancing operational efficiency, reducing scrap losses, and enabling sustainable growth in the global scrap iron magnetic suction machine market.

High initial investment costs limit adoption among small-scale players

The scrap iron magnetic suction machine market is rapidly growing as industries focus on efficient scrap handling, operational safety, and labor reduction. Advanced machines such as high-capacity magnetic lifters, automated suction systems, and industrial electromagnets provide reliable, durable, and scalable solutions for sorting and moving scrap metal.

Equally important is the adoption of smart automation and integration technologies, which ensure scrap handling processes operate efficiently and reliably. Advanced control systems, high-capacity magnets, and automated sorting units allow facilities to process larger volumes of scrap safely and consistently, while increasing demand from automotive, construction, and steel industries drives further innovation.

Geographical Penetration

Asia-Pacific Leads the Scrap Iron Magnetic Suction Machine Market Driven by Industrial Growth and Infrastructure

The Asia-Pacific region dominates the global scrap iron magnetic suction machine market, fueled by rapid industrialization, urbanization, and infrastructure development in countries such as China, India, and Japan. Rising demand from the construction, automotive, and industrial sectors is driving the adoption of advanced scrap handling solutions, including high-capacity magnetic suction machines and automated sorting systems.

Government initiatives promoting large-scale industrial and infrastructure projects, such as highways, metro networks, and smart industrial zones, are accelerating the deployment of efficient scrap handling solutions. Innovations in automation, energy-efficient machinery, and durable industrial magnets are enhancing operational performance and reliability. Combined with competitive manufacturing capabilities and abundant resources, the Asia-Pacific region is expected to maintain its leading position in the global market in the coming years.

India Scrap Iron Magnetic Suction Machine Market Outlook

India’s scrap iron magnetic suction machine market is experiencing robust growth, driven by infrastructure expansion and increasing industrial demand. Government programs, including major investments in highways, metro systems, and industrial modernization initiatives, are boosting adoption of advanced scrap handling technologies. Domestic innovation in high-capacity magnets, automated suction systems, and industrial automation is further supporting market growth. With steady economic expansion and rapid industrialization, India’s market outlook remains highly promising.

China Scrap Iron Magnetic Suction Machine Market Trends

China continues to be a global leader in scrap handling technology adoption, investing heavily in industrial automation, high-capacity magnetic suction systems, and smart factory solutions. Strong domestic demand from the industrial, automotive, and urban sectors continues to drive market expansion. Ongoing government-led infrastructure initiatives and technological advancements are accelerating deployment of efficient scrap handling solutions, ensuring China’s market remains robust and poised for steady growth in the coming years.

North America Leading the Charge in Scrap Iron Magnetic Suction Machine Adoption

North America is emerging as one of the fastest-growing regions in the scrap iron magnetic suction machine market, driven by rising demand in industrial recycling, construction, and steel manufacturing sectors. The region benefits from advanced industrial infrastructure, strong R&D capabilities, and strategic investments in automated scrap handling and high-capacity magnetic systems. The push toward operational efficiency, safety, and sustainable material reuse is accelerating adoption across multiple industrial segments. As governments, recyclers, and private manufacturers invest in modern scrap handling solutions, North America is solidifying its position as a global hub for innovation and market growth.

US Scrap Iron Magnetic Suction Machine Market Insights

In the United States, the market continues to grow steadily, supported by high industrial demand, extensive recycling operations, and strong construction activity. Rising focus on automation, operational safety, and efficient material recovery is driving adoption, while advances in magnetic suction technology and automated lifting systems are enhancing performance and reliability. With robust domestic manufacturing capabilities, supportive regulations, and increasing industrial investments, the US market is well-positioned to maintain growth while promoting sustainable and efficient scrap handling practices.

Canada Scrap Iron Magnetic Suction Machine Industry Growth

Canada’s market is experiencing steady expansion, driven by industrial growth, recycling infrastructure, and rising demand from construction and steel sectors. The country leverages advanced manufacturing, supportive policies, and innovative solutions to expand applications of high-capacity magnetic suction machines. Companies are investing in durable, energy-efficient systems and automated handling solutions, boosting operational efficiency and reliability. Continued adoption of advanced scrap handling technologies reflects Canada’s commitment to sustainable industrial practices, optimized material reuse, and long-term market growth, making it a key contributor to the broader North American scrap iron magnetic suction machine market.

Sustainability Analysis

The scrap iron magnetic suction machine market is increasingly embracing sustainability, driven by the push for efficient, eco-friendly, and low-energy industrial operations. Companies are investing heavily in automated systems, energy-efficient lifting magnets, and advanced sorting technologies to reduce operational costs and environmental impact.

Sustainable practices, including responsible sourcing of raw materials, compliance with industrial safety standards, and adherence to environmental regulations, are becoming standard across the sector. Lightweight and high-efficiency machines contribute to lower energy consumption and reduced operational emissions in steel mills, recycling yards, and industrial facilities, indirectly supporting sustainable industrial growth.

Competitive Landscape

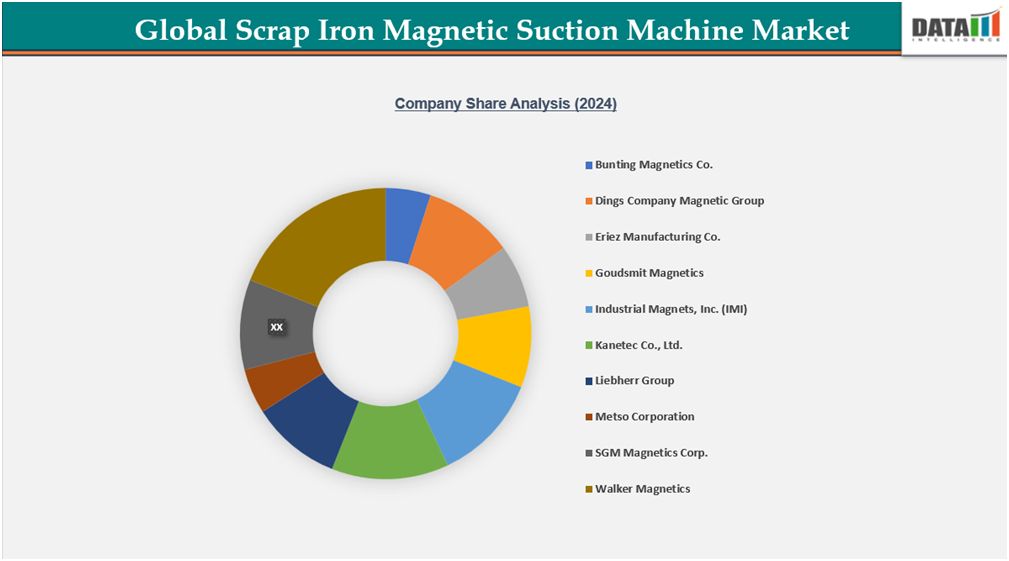

- The global scrap iron magnetic suction machine market is dominated by a mix of leading innovators and specialized product-type players. Bunting Magnetics Co., Dings Company Magnetic Group, and Eriez Manufacturing Co. are at the forefront, collectively holding a significant share, leveraging expertise in high-capacity magnetic suction systems, automated lifting solutions, and industrial magnets.

- A second tier, including Goudsmit Magnetics, Industrial Magnets, Inc. (IMI), and Kanetec Co., Ltd., focuses on regional and sector-specific solutions, particularly in Europe and Asia-Pacific, and is steadily expanding its global footprint through product innovation and specialized service offerings.

- The rest of the market is more fragmented, with companies like Liebherr Group, Metso Corporation, SGM Magnetics Corp., and Walker Magnetics offering niche solutions in custom magnetic handling systems, scrap processing, and industrial applications.

Key Developments

- January 2025 – Eriez Manufacturing Co. achieved a significant milestone by deploying 10 high-capacity scrap iron magnetic suction machines across major industrial and recycling facilities in North America, enhancing operational efficiency and throughput.

Why Choose DataM?

- Data-Driven Insights: Dive into detailed analyses with granular insights such as pricing, market shares and value chain evaluations, enriched by interviews with industry leaders and disruptors.

- Post-Purchase Support and Expert Analyst Consultations: As a valued client, you gain direct access to our expert analysts for personalized advice and strategic guidance, tailored to your specific needs and challenges.

- White Papers and Case Studies: Benefit quarterly from our in-depth studies related to your purchased titles, tailored to refine your operational and marketing strategies for maximum impact.

- Annual Updates on Purchased Reports: As an existing customer, enjoy the privilege of annual updates to your reports, ensuring you stay abreast of the latest market insights and technological advancements. Terms and conditions apply.

- Specialized Focus on Emerging Markets: DataM differentiates itself by delivering in-depth, specialized insights specifically for emerging markets, rather than offering generalized geographic overviews. This approach equips our clients with a nuanced understanding and actionable intelligence that are essential for navigating and succeeding in high-growth regions.

- Value of DataM Reports: Our reports offer specialized insights tailored to the latest trends and specific business inquiries. This personalized approach provides a deeper, strategic perspective, ensuring you receive the precise information necessary to make informed decisions. These insights complement and go beyond what is typically available in generic databases.

Target Audience 2024

- Manufacturers/ Buyers

- Industry Investors/Investment Bankers

- Research Professionals

- Emerging Companies