Global CNC Milling Machines Market Size

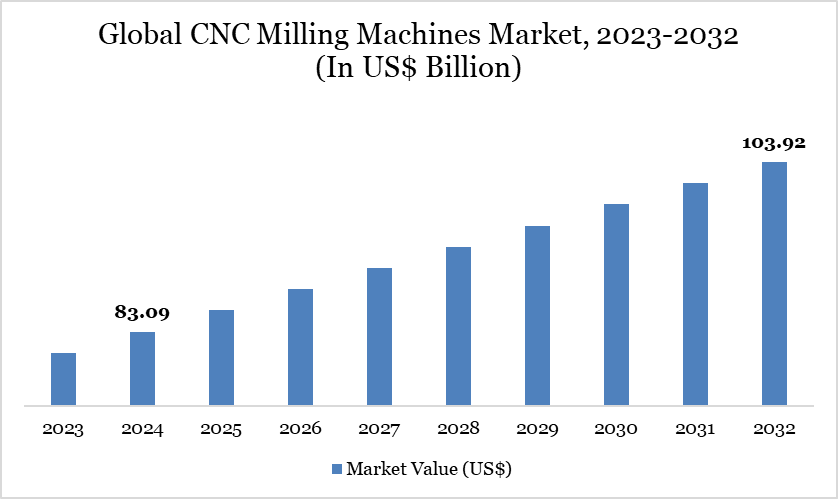

Global CNC Milling Machines Market reached US$ 83.09 billion in 2024 and is expected to reach US$ 103.92 billion by 2032, growing with a CAGR of 2.99% during the forecast period 2025-2032.

The global CNC milling machines market is experiencing robust growth, driven by increasing demand for precision-engineered components, industrial automation, and flexible manufacturing solutions across key sectors such as automotive, aerospace, electronics, and industrial machinery. CNC milling machines, including vertical and horizontal configurations, are essential for producing complex geometries with high accuracy, surface quality, and repeatability.

echnological advancements such as multi-axis machining, AI-enabled adaptive control, real-time monitoring, and hybrid additive-subtractive systems are transforming manufacturing processes and boosting operational efficiency. The market is further supported by rising investments in smart factories, Industry 4.0 initiatives, and modernization programs worldwide, enabling manufacturers to enhance productivity, reduce costs, and meet stringent quality requirements. Regions like Asia-Pacific are emerging as major growth hubs due to strong industrial development, increasing automation adoption, and government support for advanced manufacturing infrastructure.

Global CNC Milling Machines Market Trend

One of the most prominent trends in the global CNC milling machines market is the integration of artificial intelligence (AI) and machine learning (ML) into machining operations, enabling adaptive tool path optimization, predictive maintenance, and real-time process adjustments to improve precision and efficiency.

Another major trend is the development of compact, modular, and multi-axis CNC milling machines, which allow for space-efficient layouts, faster setup times, and versatile production of complex components across industries, from automotive to aerospace.

Additionally, the market is witnessing a shift toward hybrid manufacturing systems that combine additive and subtractive processes, enabling faster prototyping, expanded material capabilities, and reduced production costs, while supporting flexible, high-precision manufacturing for modern industrial requirements.

Market Scope

Metrics | Details |

By Product Type | Vertical CNC Milling Machines, Horizontal CNC Milling Machines, Universe CNC Milling Machines |

By Axis Type | 3-axis milling machines, 4-axis milling machines, 5-axis milling machines |

By End-users | Automotive, Aerospace, Electronics & Electrical , Others |

By Region | North America, South America, Europe, Asia-Pacific, Middle East and Africa |

Report Insights Covered | Competitive Landscape Analysis, Company Profile Analysis, Market Size, Share, Growth |

Market Dynamics

Growing Investments in Industrial Automation and Manufacturing Modernization Worldwide

Global investments in industrial automation and modernization initiatives are a key driver of the CNC milling machines market, as manufacturers focus on upgrading production capabilities, enhancing precision, and boosting operational efficiency. In 2024, Japanese automotive and aerospace companies made significant investments in next-generation 5-axis CNC milling machines, enabling faster production cycles and the manufacture of complex components with improved accuracy.

Likewise, China’s 2025 smart factory programs incorporated AI-enabled CNC milling systems with adaptive control and real-time monitoring, highlighting the increasing demand for flexible, high-performance manufacturing solutions. These ongoing investments are creating a strong procurement pipeline for advanced CNC machinery, supporting sustained global market growth.

Cybersecurity and Operational Challenges

Cybersecurity vulnerabilities and operational risks are notable restraints for the CNC milling machines market, as modern systems rely heavily on interconnected digital platforms, IoT-enabled networks, and software-driven automation. Advanced control systems, cloud-based monitoring, and AI-assisted machining can expose manufacturers to cyberattacks, data breaches, or system failures, potentially disrupting production, compromising sensitive designs, or causing costly downtime. Addressing these challenges requires significant investment in secure software, cybersecurity measures, and continuous system monitoring, which adds complexity, prolongs deployment timelines, and increases overall operational costs.

Segment Analysis

The global CNC Milling Machines market is segmented based on product type, axis type, end-users and region.

Modernization of Manufacturing Operations and Advanced Automation in Vertical CNC Milling Machines

The Vertical CNC Milling Machines segment is a key driver of the global CNC milling machines market, propelled by the modernization of manufacturing operations and the integration of advanced automation and digital technologies. This segment benefits from rising adoption of multi-axis machining, AI-enabled tool path optimization, adaptive control systems, and real-time monitoring solutions to improve precision, throughput, and operational efficiency across automotive, aerospace, and industrial equipment sectors.

For instance, in 2024, Japanese automotive manufacturers deployed next-generation 5-axis vertical CNC milling machines to produce complex engine and chassis components with higher accuracy and reduced cycle times. Similarly, in 2025, Chinese aerospace firms integrated AI-driven vertical CNC milling systems into smart factories, enabling adaptive machining and predictive maintenance to enhance production reliability and component quality.

Geographical Penetration

Increasing Investments in Advanced CNC Milling Machines Across Asia-Pacific

The Asia-Pacific CNC milling machines market is witnessing strong growth, driven by advancements in automated manufacturing systems and the adoption of state-of-the-art machining technologies by regional industrial leaders to boost productivity, precision, and competitiveness. In 2024, Japan implemented next-generation 5-axis CNC milling machines in its aerospace and automotive industries, aiming to enhance component quality, reduce production cycles, and support complex manufacturing requirements, reflecting the rising demand for advanced production solutions.

In 2025, China launched a smart factory initiative featuring AI-enabled CNC milling systems with adaptive machining and real-time monitoring capabilities, underscoring the region’s focus on digitalized, high-efficiency manufacturing. These trends demonstrate how Asia-Pacific’s commitment to modernizing industrial infrastructure with cutting-edge CNC milling technology is driving market expansion, as manufacturers respond to growing needs for precision-engineered components and flexible production processes.

Technological Analysis

The technological landscape of the global CNC milling machines market is rapidly advancing, driven by innovations in computer numerical control (CNC) systems, automation, artificial intelligence (AI), and Internet of Things (IoT) integration that enhance precision, productivity, and flexibility across manufacturing operations. Modern CNC milling machines incorporate multi-axis machining capabilities, high-speed spindles, and adaptive control systems to enable complex geometries and superior surface finishes. Additive manufacturing integration and hybrid machining technologies are expanding material versatility and reducing cycle times. Advanced sensors, real-time monitoring, and predictive maintenance software are improving operational efficiency, minimizing downtime, and enabling smart factory operations in aerospace, automotive, and precision engineering sectors.

Competitive Landscape

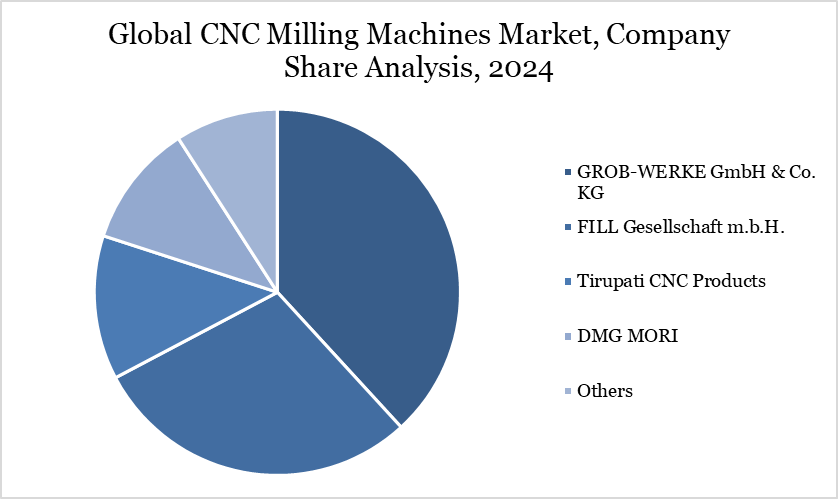

The major global players in the market include GROB-WERKE GmbH & Co. KG, FILL Gesellschaft m.b.H., Tirupati CNC Products, DMG MORI, DN SOLUTIONS, Doosan Precision Engineering Ltd, Hwacheon, Weihai Huadong Automation Co., Ltd, Makino Inc, GF Machining Solutions Management SA and among others.

Why Choose DataM?

Data-Driven Insights: Dive into detailed analyses with granular insights such as pricing, market shares and value chain evaluations, enriched by interviews with industry leaders and disruptors.

Post-Purchase Support and Expert Analyst Consultations: As a valued client, gain direct access to our expert analysts for personalized advice and strategic guidance, tailored to your specific needs and challenges.

White Papers and Case Studies: Benefit quarterly from our in-depth studies related to your purchased titles, tailored to refine your operational and marketing strategies for maximum impact.

Annual Updates on Purchased Reports: As an existing customer, enjoy the privilege of annual updates to your reports, ensuring you stay abreast of the latest market insights and technological advancements. Terms and conditions apply.

Specialized Focus on Emerging Markets: DataM differentiates itself by delivering in-depth, specialized insights specifically for emerging markets, rather than offering generalized geographic overviews. This approach equips our clients with a nuanced understanding and actionable intelligence that are essential for navigating and succeeding in high-growth regions.

Value of DataM Reports: Our reports offer specialized insights tailored to the latest trends and specific business inquiries. This personalized approach provides a deeper, strategic perspective, ensuring you receive the precise information necessary to make informed decisions. These insights complement and go beyond what is typically available in generic databases.

Target Audience 2024

Manufacturers/ Buyers

Industry Investors/Investment Bankers

Research Professionals

Emerging Companies