The global industrial 3D printing gases market Overview

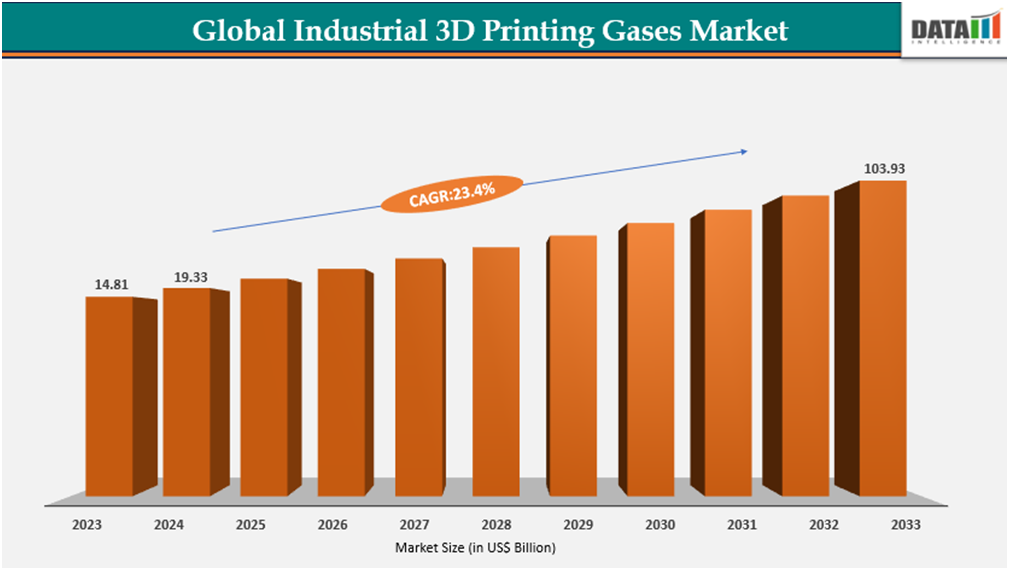

The global industrial 3D printing gases market reached US$19.33 billion in 2024 and is expected to reach US$103.93 billion by 2032, growing at a CAGR of23.4% during the forecast period 2025–2032.

The global industrial 3D printing gases market represents a vital segment of the additive manufacturing industry, valued for its role in enhancing print quality, precision, and material performance across sectors such as aerospace, automotive, healthcare, and electronics. With industries increasingly emphasizing sustainability, efficiency, and high-performance production, specialty gases like nitrogen, argon, and oxygen are becoming indispensable for ensuring consistent, defect-free prints. The market is driven by rising adoption of 3D printing technologies, ongoing innovation in gas supply solutions, and growing demand for environmentally-friendly and cost-efficient manufacturing processes on a global scale.

Trends and Strategic Insights

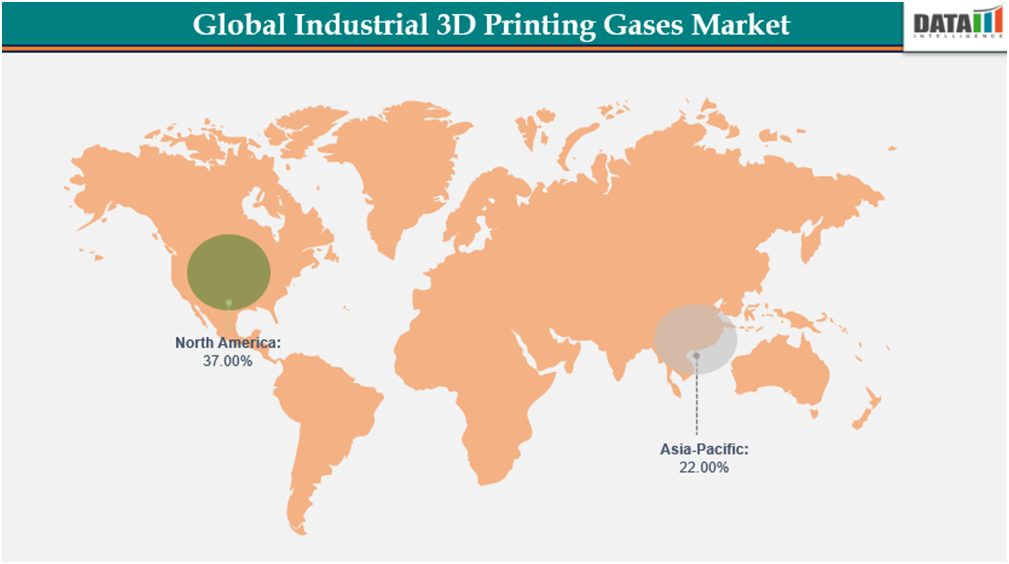

The North America region dominates the market, capturing the largest revenue share of xx % in 2024.

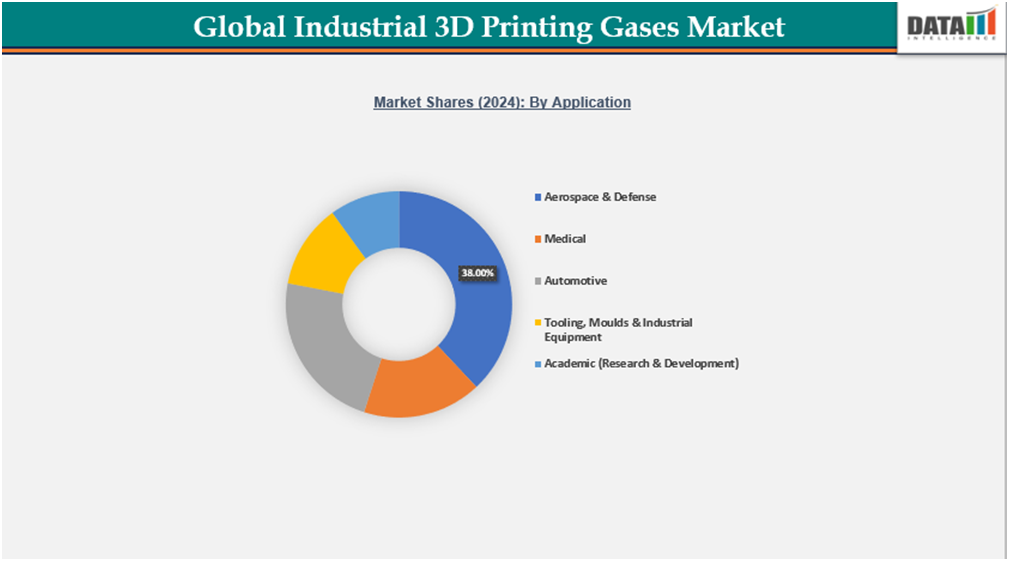

By Application, the Aerospace & Defense segment experienced the largest market, registering a significant xx % in 2024.

Market Size and Future Outlook

2024 Market Size: US$19.33 Billion

2032 Projected Market Size: US$103.93Billion

CAGR (2025-2032):23.4%

Largest Market: North America

Fastest Market: Asia-Pacific

Market Scope

Metrics | Details |

By Gas Type | Argon, Nitrogen, Helium, Hydrogen, Carbon Dioxide, Others |

By Purity | Ultra-High-Purity, High-Purity |

By Technology | Laser Powder Bed Fusion (LPBF), Electron Beam Melting (EBM), Directed Energy Deposition (DED), Binder-Jetting, Stereolithography / PolyJet / FDM |

By Application | Aerospace & Defense, Medical, Automotive, Tooling, Moulds& Industrial Equipment, Academic (Research & Development) |

By Region | North America, South America, Europe, Asia-Pacific, Middle East and Africa |

Report Insights Covered | Competitive Landscape Analysis, Company Profile Analysis, Market Size, Share, Growth |

Market Dynamics

Rising Aerospace and Medical Adoption Fuels Demand for High-Purity Gases

Industrial 3D printing gases are increasingly critical across a broad range of end-use industries, including aerospace, medical, automotive, tooling, and research & development. The growing adoption of additive manufacturing for lightweight components, precision parts, and complex geometries is driving demand for high-purity inert, shielding, and reactive gases. Industries are leveraging these gases to enhance print quality, improve mechanical properties, and ensure consistent material deposition. Rising requirements for reliability, performance, and process efficiency in high-value applications such as aerospace parts and medical devices are accelerating the uptake of industrial 3D printing gases globally.

High Production and Purification Costs Limit Affordability Across Emerging Economies

The industrial and aerospace sectors are the largest consumers of industrial 3D printing gases, driven by the growing adoption of additive manufacturing for precision parts, metal components, and high-performance prototypes. Rising demand for high-purity gases is accompanied by challenges such as high production and purification costs, which can limit affordability in emerging economies. To address these issues, enterprises are investing in efficient gas production technologies, recycling methods, and cost-optimization strategies. These efforts help companies improve accessibility, enhance sustainability, and support the broader adoption of 3D printing technologies across diverse industries globally.

Segmentation Analysis

The global industrial 3D printing gases market is segmented based on gas type, purity, technology, application, and region.

Dominating Segment: Blow-Molded Products Driving Packaging Applications

The Asia-Pacific region is emerging as a key growth area for industrial 3D printing gases, driven by the rapid expansion of manufacturing hubs in countries such as China, India, and Japan. Industries including aerospace, automotive, medical, and tooling are increasingly adopting additive manufacturing technologies, creating strong regional demand for high-purity inert, shielding, and reactive gases. The growth of manufacturing infrastructure, coupled with rising investments in advanced 3D printing facilities, is opening lucrative opportunities for gas suppliers to cater to these untapped markets and support the region’s industrial transformation.

Geographical Penetration

North America's Market Leadership and Technological Advancements

North America holds a significant share of the global industrial 3D printing gases market, supported by mature industrial adoption, high automation levels, and advanced additive manufacturing infrastructure. The U.S. is the largest regional contributor, driven by strong demand in aerospace, automotive, medical, and tooling sectors. Technological advancements focus on improving gas purity, process efficiency, and sustainable practices. Canada contributes through innovations in high-purity gases and niche applications in research & development and industrial manufacturing.

United States Industrial 3D Printing Gases Market Insights

The United States represents one of the most mature and advanced markets for industrial 3D printing gases, propelled by a large-scale industrial base and widespread adoption of additive manufacturing. High demand from aerospace and medical applications, along with growing use in automotive and tooling industries, drives market expansion. Additionally, increasing focus on process optimization, safety, and sustainability is fostering innovations in high-purity gas production. The U.S. market captures a significant share of the North American market, supported by leading industry players and strategic manufacturing investments.

Canada Industrial 3D printing gases Industry Growth

Canada accounts for a stable portion of the North American industrial 3D printing gases market, underpinned by rising adoption in aerospace, research, and industrial manufacturing applications. Investments in sustainable infrastructure, environmental initiatives, and technological innovations in gas production are boosting market prospects. Canadian suppliers are focusing on differentiated offerings, including high-purity gases for precision applications, driven by demand from niche industrial and research sectors.

Asia Pacific's Rapid Industrialization and Infrastructure Demand

Asia Pacific (APAC) is poised to be the fastest-growing region for industrial 3D printing gases, driven by rapid industrialization, urbanization, and large-scale investments in manufacturing and infrastructure. China leads the region with strong adoption of additive manufacturing in aerospace, automotive, and industrial tooling sectors, supported by leading domestic gas suppliers and advanced R&D initiatives. India is emerging as a high-growth market due to expanding industrial bases, infrastructure projects, and rising adoption of 3D printing technologies in medical, automotive, and packaging applications. Southeast Asia’s expanding manufacturing ecosystem is further fueling regional demand for high-purity and specialty industrial 3D printing gases.

India Industrial 3D Printing Gases Market Outlook

India is among the fastest-growing markets globally for industrial 3D printing gases, propelled by increasing industrial adoption, population growth, and rising use of additive manufacturing across aerospace, automotive, and healthcare sectors. Expanding infrastructure projects, a growing number of 3D printing facilities, and a robust network of domestic supplier’s support market growth. Regulatory emphasis on safety, environmental standards, and sustainable practices further drives the adoption of high-purity and specialty gases.

China Industrial 3D Printing Gases Market Trends

China dominates the APAC industrial 3D printing gases market, backed by strong government policies supporting additive manufacturing and industrial modernization. Regulations encouraging sustainability and efficiency are driving innovation in high-performance and environmentally-friendly gas solutions. Leading domestic producers are investing in R&D to develop specialty gases for aerospace, medical, automotive, and industrial applications, catering to both domestic and export markets. The focus remains on precision, process reliability, and supporting high-value additive manufacturing sectors.

Sustainability Analysis

Industrial 3D printing gases play a critical role in promoting sustainability in additive manufacturing. They enable reduced material wastage, improved energy efficiency, and longer-lasting performance of printed components across aerospace, medical, automotive, and industrial tooling applications. However, environmental concerns persist due to challenges in gas production, handling, and disposal.

Industry leaders are investing in advanced purification technologies, recycling methods, and closed-loop supply chains to minimize environmental impact. Regulatory frameworks are encouraging eco-friendly practices, prompting companies to innovate in sustainable gas solutions, reduce lifecycle emissions, and support greener additive manufacturing processes.

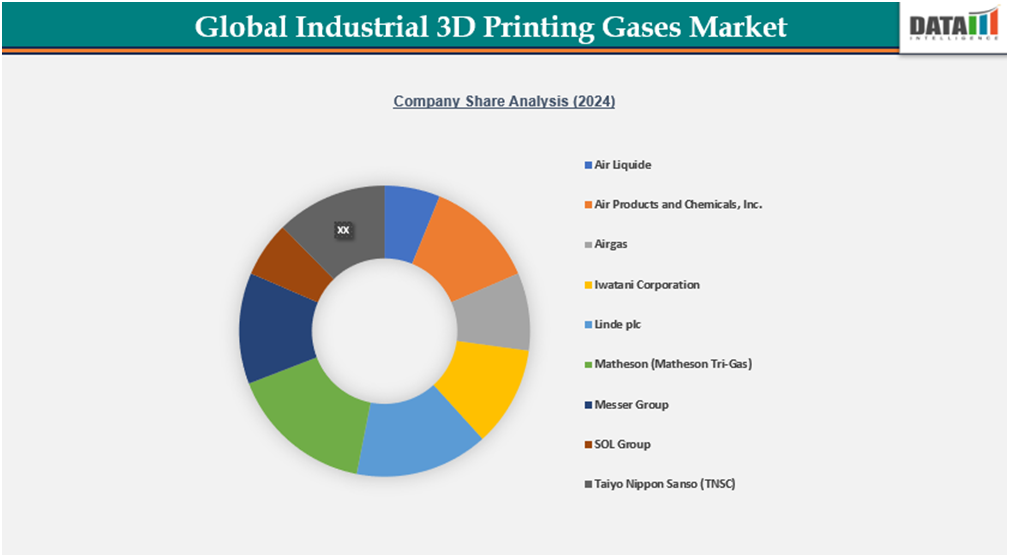

Competitive Landscape

The global industrial 3D printing gases market is highly competitive and consolidated, driven by leading industrial gas suppliers focusing on economies of scale, production efficiency, and global market expansion.

Key players leverage extensive production networks, large-scale R&D investments, and robust distribution channels to maintain leadership.

Companies are developing high-purity and specialty gases tailored for additive manufacturing applications in aerospace, medical, automotive, and industrial tooling sectors.

Market participants are innovating in sustainable gas solutions, including recycling methods and closed-loop supply chains, to enhance environmental credentials.

Strategic partnerships, facility expansions, and technological advancements are core strategies to strengthen competitive positioning.

High-performance and differentiated gas solutions enable superior process reliability, product quality, and compliance with evolving global environmental regulations.

Key Developments

Linde plc expanded its portfolio of high-purity gases for additive manufacturing in 2025, launching advanced argon and nitrogen supply solutions designed to improve process consistency and surface quality in metal 3D printing applications.

Why Choose DataM?

Data-Driven Insights: Dive into detailed analyses with granular insights such as pricing, market shares, and value chain evaluations, enriched by interviews with industry leaders and disruptors.

Post-Purchase Support and Expert Analyst Consultations: As a valued client, gain direct access to our expert analysts for personalized advice and strategic guidance, tailored to your specific needs and challenges.

White Papers and Case Studies: Benefit quarterly from our in-depth studies related to your purchased titles, tailored to refine your operational and marketing strategies for maximum impact.

Annual Updates on Purchased Reports: As an existing customer, enjoy the privilege of annual updates to your reports, ensuring you stay abreast of the latest market insights and technological advancements. Terms and conditions apply.

Specialized Focus on Emerging Markets: DataM differentiates itself by delivering in-depth, specialized insights specifically for emerging markets, rather than offering generalized geographic overviews. This approach equips our clients with a nuanced understanding and actionable intelligence that are essential for navigating and succeeding in high-growth regions.

Value of DataM Reports: Our reports offer specialized insights tailored to the latest trends and specific business inquiries. This personalized approach provides a deeper, strategic perspective, ensuring you receive the precise information necessary to make informed decisions. These insights complement and go beyond what is typically available in generic databases.

Target Audience 2024

Manufacturers/ Buyers

Industry Investors/Investment Bankers

Research Professionals

Emerging Companies