Self-Healing Materials Market Size

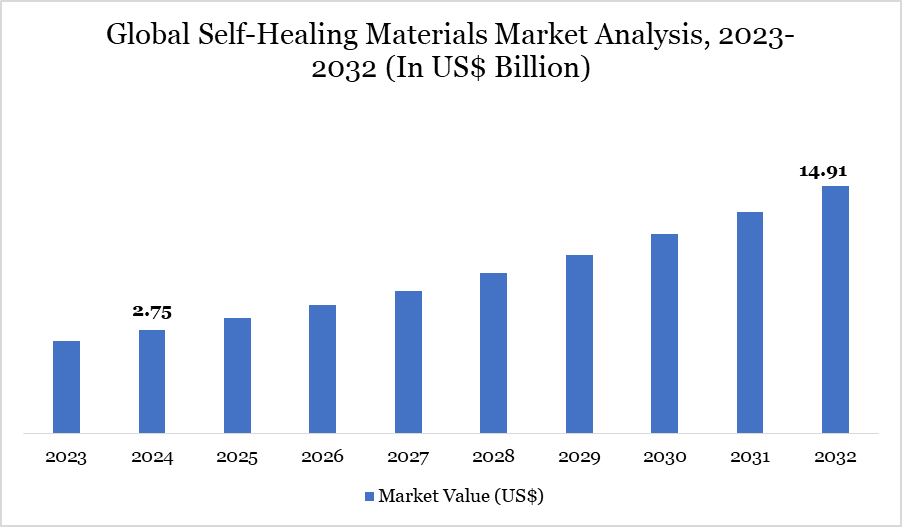

Self-Healing Materials Market Size reached US$ 2.75 billion in 2024 and is expected to reach US$ 14.91 billion by 2032, growing with a CAGR of 23.53% during the forecast period 2025-2032.

The global market for self-healing materials is experiencing significant expansion driven by rising demand in the construction, automotive, and electronics sectors. These materials are designed to autonomously mend damages, such as microcracks induced by external factors, including UV radiation, pH fluctuations, or mechanical stress, thus reinstating functioning.

Advanced technologies such as microcapsules, hollow glass fibers, and optical fibers are essential to self-repairing mechanisms, whether intrinsic or extrinsic. In the United States, expansion is bolstered by multinational firms that are significantly spending in research and development to create next-generation self-healing technologies.

The market expansion is further augmented by the increasing demand in economical maintenance options. In the building industry, self-healing cement and mortar are progressively utilized to mitigate long-term structural degradation. The enhancement of service life and reduction in repair frequency are augmenting the commercial feasibility of these materials.

Self-Healing Materials Market Trend

A significant trend in the self-healing materials market is the increasing incorporation of these materials into the wind power industry. Wind turbines employ composite materials, specifically fiberglass-reinforced plastic (FRP), owing to their superior strength-to-weight ratio, flexibility, and longevity. As wind turbine blades increase in length and complexity to enhance efficiency, the requirement for materials capable of enduring fatigue and environmental degradation escalates.

Glass serves as the principal construction material for turbine blades, supplemented by steel (71–79%), resin/plastic (11–16%), and iron (5–17%). The advancement of self-healing composites, particularly those that repair damage at the micron level, is addressing industrial need for more durable turbine components.

The versatility of these materials in creating complex geometries enhances blade customization. Thus, the ongoing global growth of wind energy infrastructure is poised to enhance the utilization of self-healing materials in turbine production, establishing a robust, sustained market trend.

For more details on this report, Request for Sample

Market Scope

| Metrics | Details | |

| By Form | Intrinsic, Extrinsic | |

| By Product | Concrete, Coatings, Polymers, Asphalt, Fiber-reinforced Composites, Ceramic, Metals | |

| By Technology | Reversible Polymers, Microencapsulation, Shape Memory Materials, Biological Material Systems, Others | |

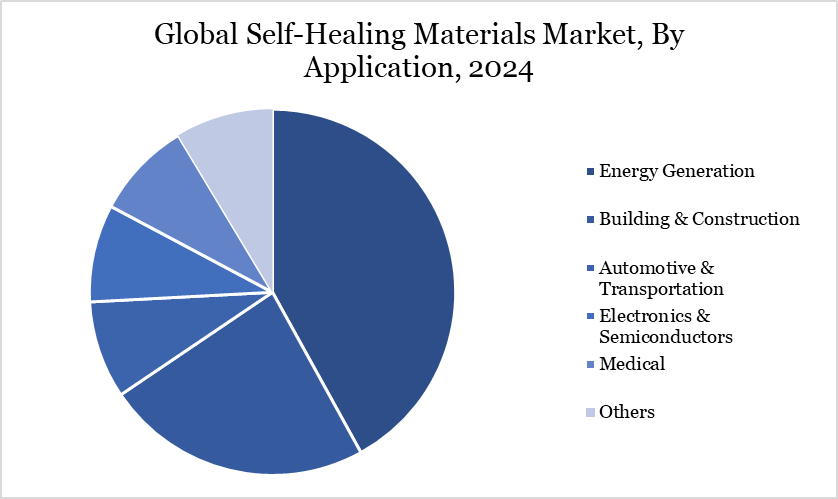

| By Application | Energy Generation, Building & Construction, Automotive & Transportation, Electronics & Semiconductors, Medical, Others | |

| By Region | North America, South America, Europe, Asia-Pacific, Middle East and Africa | |

| Report Insights Covered | Competitive Landscape Analysis, Company Profile Analysis, Market Size, Share, Growth |

Self-Healing Materials Market Dynamics

Increasing Infrastructure and Urbanization Driving Demand

The swift growth of the worldwide construction industry is a primary catalyst for the self-healing materials market. Conventional concrete, despite its prevalent use, is prone to microcracking, which allows moisture and chemicals to infiltrate and undermine structural integrity. Self-healing technologies, especially microcapsule-based systems, resolve this problem by autonomously mending fissures via the release of healing chemicals. These solutions have demonstrated significant efficacy under many environmental circumstances, including thermal, mechanical, and hydraulic stress.

Emerging economies such as India are leading, propelled by swift industrialization, urban migration, and extensive public infrastructure construction. Initiatives like "Make in India" enhance domestic production and improve access to construction-grade raw materials, hence promoting the use of innovative building technology.

Furthermore, heightened awareness of advantages such as quick fracture recovery, enhanced durability, and long-term cost efficiency is driving market demand. Self-healing materials are essential elements in the advancement of contemporary infrastructure systems.

Constraints of Material Design and Restricted Repair Capabilities

The market expansion for self-healing materials encounters substantial obstacles, chiefly because to the restricted efficacy of healing agents. These drugs, frequently contained within microcapsules, are diminutive and prone to rupture under stress. Nonetheless, their diminutive size constrains the quantity of healing agent accessible, hence restricting the magnitude and frequency of repair that a material may endure.

Upon the rupture of the microcapsules, the healing mechanism becomes irreversible, diminishing long-term efficacy. This is especially concerning in high-pressure settings when polymers and capsules may succumb to mechanical stress. The lack of capacity for ongoing self-repair without reapplication restricts the utilization of these materials in applications necessitating sustained or recurrent stress resistance. Consequently, although self-healing materials are optimal for initial damage mitigation, their limited healing capacity and the disposable nature of the microcapsules provide significant obstacles, particularly in sectors demanding high durability and several repair cycles.

Self-Healing Materials Market Segment Analysis

The global self-healing materials market is segmented based on form, product, technology, application and region.

Driving Innovation in Mobility reflects the growing use of smart materials to enhance vehicle performance, longevity, and sustainability

Self-healing materials are emerging as revolutionary solutions in the automotive and transportation sector, providing substantial improvements in durability, safety, and maintenance efficiency. These materials may self-repair damage, hence prolonging the operating lifespan of vehicle components and diminishing long-term maintenance expenses.

Applications include self-healing coatings, like those created by KRICT and utilized in BMW's iX model, as well as transparent sensor lenses that mend scratches, hence enhancing reliability in autonomous vehicles. Tires equipped with integrated self-sealing mechanisms and elastomeric substances such as self-healing EPDM significantly improve vehicle durability. Innovations such as the Lamborghini-MIT Terzo Millennio utilize carbon fiber composites embedded with nanotubes to autonomously repair structural damage, emulating biological systems.

Notwithstanding these encouraging advancements, broad implementation encounters obstacles such as elevated production expenses, restricted scalability, and reliance on particular environmental stimuli. As research advances, self-healing materials are set to transform vehicle design, enhancing safety, intelligence, and sustainability in transportation systems.

Self-Healing Materials Market Geographical Share

Asia Pacific Dominates the Self-Healing Materials Market Driven by Rapid Urbanization and Industrial Growth

The Asia-Pacific region is witnessing significant growth in the self-healing materials market, propelled by swift urbanization, industrialization, and infrastructural advancement. In 2023, China spearheaded the area, bolstered by its preeminent automotive industry and its position as a global exporter of vehicle components.

Prominent car manufacturers, including Volkswagen, are expanding their operations in China, hence enhancing the need for innovative materials like self-healing composites. Countries such as India are concurrently experiencing a surge in construction activities driven by an increasing population, rural-to-urban migration, and extensive urban infrastructure initiatives.

These trends are anticipated to markedly elevate the demand for self-healing concrete and associated materials. The wider region advantages from an extensive consumer market, reduced labor expenses, escalating per capita income, and growing foreign investments in automobile and electronics production. Countries in Southeast Asia, such as Indonesia and Vietnam, are emerging as viable markets. Collectively, these elements position Asia-Pacific as a pivotal growth driver for the self-healing materials sector.

Sustainability Analysis

Sustainability continues to be a fundamental principle in the expansion of the self-healing materials business. These intelligent materials provide considerable ecological benefits by diminishing the necessity for maintenance and replacements, therefore prolonging the lifespan of products and infrastructure. The capacity for self-repair reduces material waste and diminishes lifecycle emissions linked to frequent rebuilding or component replacement.

In the construction business, self-healing cement diminishes the necessity for supplementary raw materials and the energy-intensive repair processes commonly linked to traditional building methods. Furthermore, less downtime and resource use in the automotive and electronics industries enhance environmental performance.

Technologies like microcapsule healing mechanisms and bio-inspired composites emulate natural processes, fostering environmentally sustainable innovation. As global enterprises adopt circular economy concepts, the incorporation of sustainable self-healing technologies not only bolsters green initiatives but also conforms to regulatory frameworks aimed at reducing carbon footprints and improving materials efficiency.

Self-Healing Materials Market Players

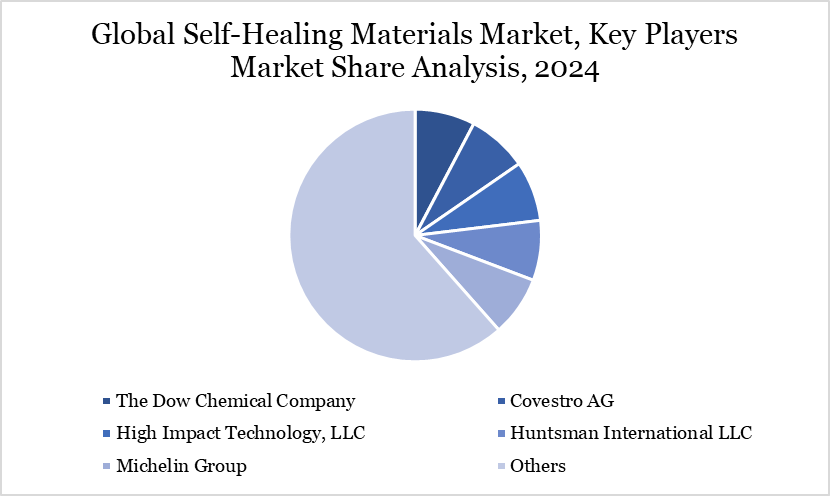

The major global players in the market include The Dow Chemical Company, Covestro AG, High Impact Technology, LLC, Huntsman International LLC, Michelin Group, MacDermid Autotype Ltd., Akzo Nobel N.V., Evonik Industries Corporation, BASF SE, and NEI Corporation.

Key Developments

- In October 2023, DuPont introduced COASTALUME in collaboration with US Steel. This material is specifically engineered to endure coastal situations. It integrates the self-healing properties and durability of US Steel’s GALVALUME with DuPont's Tedlar PVF film barrier, capable of resisting seawater corrosion, cracking, and ultraviolet damage, among other factors. The forthcoming product launch is anticipated to fulfill the need for a product in residential and commercial buildings across North America.

- In August 2022, BASF SE launched RODIM Thermoplastic Polyurethane Paint Protection Film to enhance automotive paint protection. The product demonstrated exceptional resilience to environmental factors, including elevated temperatures and extended ultraviolet exposure, during a 3,000-hour accelerated UV test. This aims to furnish firms with a competitive advantage.

Why Choose DataM?

- Data-Driven Insights: Dive into detailed analyses with granular insights such as pricing, market shares and value chain evaluations, enriched by interviews with industry leaders and disruptors.

- Post-Purchase Support and Expert Analyst Consultations: As a valued client, gain direct access to our expert analysts for personalized advice and strategic guidance, tailored to your specific needs and challenges.

- White Papers and Case Studies: Benefit quarterly from our in-depth studies related to your purchased titles, tailored to refine your operational and marketing strategies for maximum impact.

- Annual Updates on Purchased Reports: As an existing customer, enjoy the privilege of annual updates to your reports, ensuring you stay abreast of the latest market insights and technological advancements. Terms and conditions apply.

- Specialized Focus on Emerging Markets: DataM differentiates itself by delivering in-depth, specialized insights specifically for emerging markets, rather than offering generalized geographic overviews. This approach equips our clients with a nuanced understanding and actionable intelligence that are essential for navigating and succeeding in high-growth regions.

- Value of DataM Reports: Our reports offer specialized insights tailored to the latest trends and specific business inquiries. This personalized approach provides a deeper, strategic perspective, ensuring you receive the precise information necessary to make informed decisions. These insights complement and go beyond what is typically available in generic databases.

Target Audience 2024

- Manufacturers/ Buyers

- Industry Investors/Investment Bankers

- Research Professionals

- Emerging Companies