Low-Density Polyethylene (LDPE) Market Size & Overview

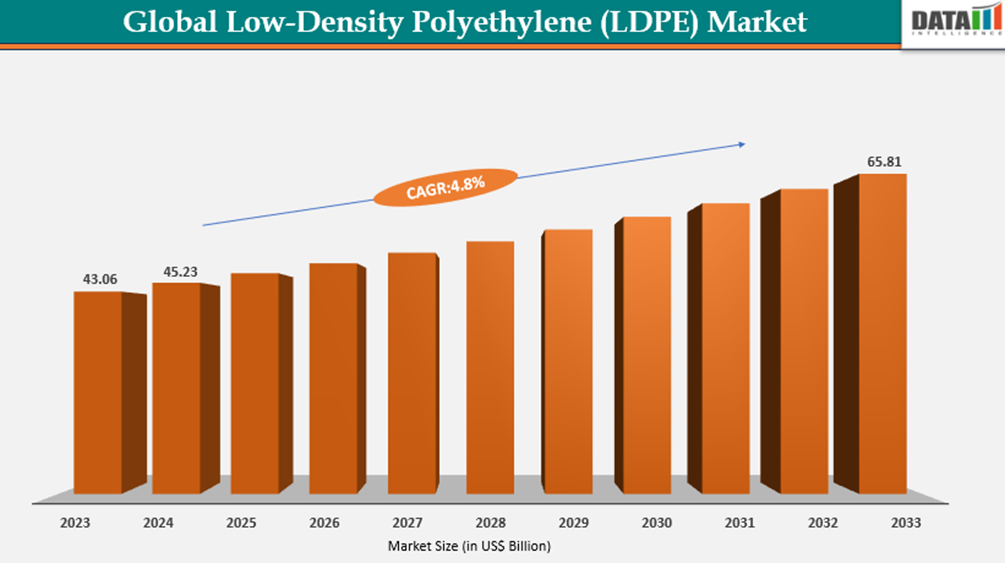

The global Low-Density Polyethylene (LDPE) Market reached US$45.23 billion in 2024 and is expected to reach US$65.81 billion by 2032, growing at a CAGR of 4.8% during the forecast period 2025-2032.

The global Low-Density Polyethylene (LDPE) market exemplifies a critical segment of the broader plastics industry, characterized by its wide range of applications and versatility in sectors like packaging, automotive, agriculture, and consumer goods. As the world increasingly focuses on sustainability, efficiency, and performance, LDPE’s unique properties—such as high flexibility, transparency, and chemical resistance position it as a preferred polymer for various industrial and consumer applications. The market operates on a global scale, driven by evolving customer demands, innovative product development, and the transition towards more environmentally-friendly production practices.

Low-Density Polyethylene (LDPE) Industry Trends and Strategic Insights

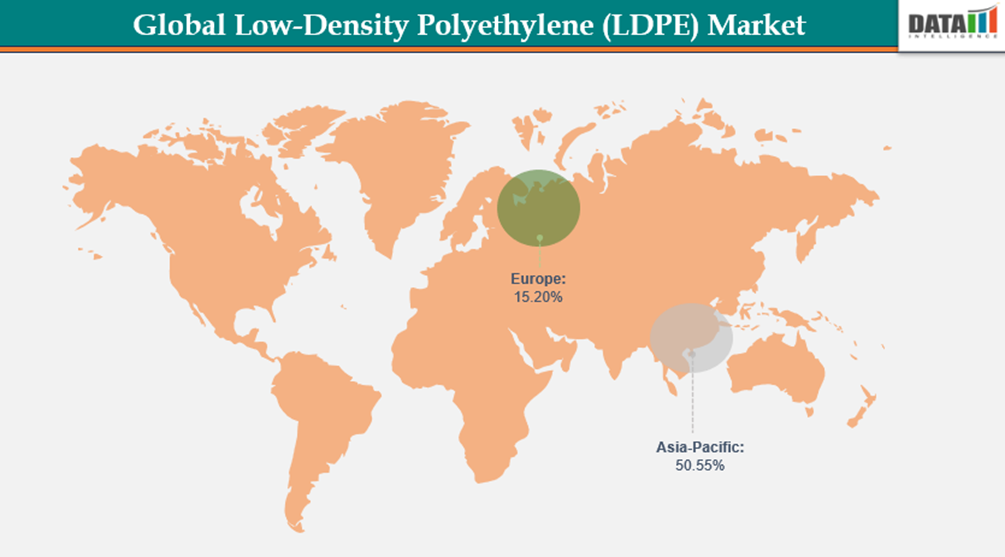

The Asia-Pacific region dominates the market, captured the largest revenue share of 50.55% in 2024.

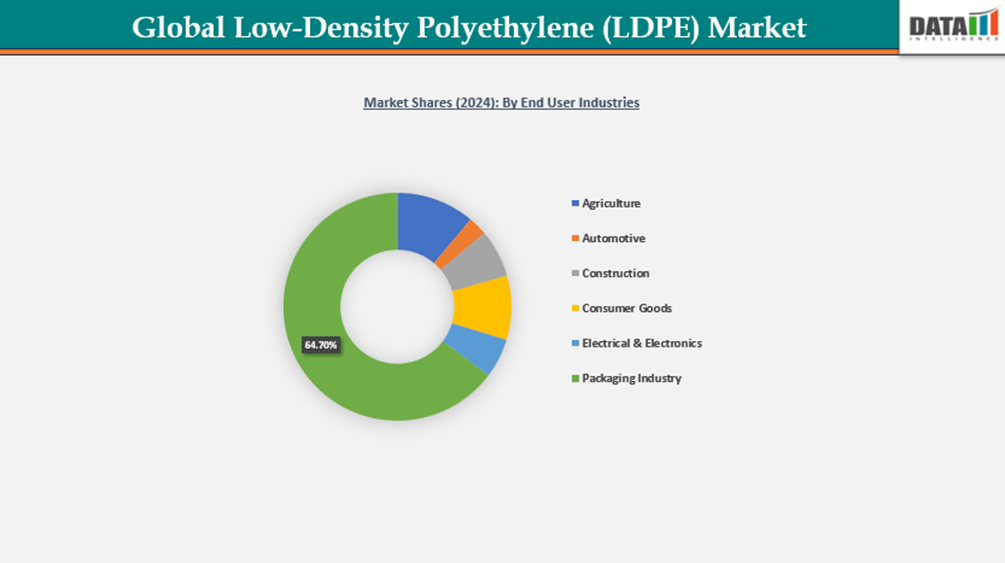

By end-user industries, the packaging industry experienced the largest market, registering a significant 64.70% in 2024.

Market Size and Future Outlook

2024 Market Size: US$45.23 Billion

2032 Projected Market Size: US$65.81 Billion

CAGR (2025-2032): 4.8%

Largest Market: Asia-Pacific

Fastest Market: Europe

Market Scope

Metrics | Details |

By Product Type | Blow Molded, Films & Sheets, Injection Molded, Extrusion Coating, Others |

By Manufacturing Process | Tubular Method, Autoclave Method |

By Feedstock | Naphtha, Natural Gas, Others |

By End-User Industries | Agriculture, Automotive, Construction, Consumer Goods, Electrical & Electronics, Packaging Industry |

By Region | North America, South America, Europe, Asia-Pacific, Middle East and Africa |

Report Insights Covered | Competitive Landscape Analysis, Company Profile Analysis, Market Size, Share, Growth |

Market Dynamics

Proliferation of Applications Across Diverse Industries

LDPE’s adaptability allows it to serve a broad spectrum of end-user industries, from agriculture to electrical & electronics. The modern industrial landscape is experiencing dynamic shifts, and LDPE is central to solutions such as flexible packaging, insulation materials, agricultural films, and molded consumer products. The surge in e-commerce, the agricultural need for durable and flexible films, and robust demand from construction and consumer goods sectors are accelerating LDPE adoption. The material’s chemical stability and processability allow it to seamlessly integrate into extrusion, blow molding, injection molding, and other advanced manufacturing methods, enabling enterprises to meet industry-specific challenges efficiently and cost-effectively.

Widespread Adoption of Sustainable Packaging Solutions

The packaging industry represents the largest consumer of LDPE, primarily driven by the growth of flexible packaging solutions. Increasing consumer awareness around packaging sustainability, coupled with stringent government regulations on plastic use and waste management, has catalyzed innovations in recyclable and biodegradable LDPE formulations. Enterprises are transitioning towards circular economy models, emphasizing the use of recycled LDPE materials and developing energy-efficient processing technologies. These trends enable companies to reduce costs, enhance brand reputation, and meet evolving compliance requirements.

Segment Analysis

The global Low-Density Polyethylene (LDPE) market is segmented based on product type, manufacturing process, feedstock, end-user industries, and region.

Dominating Segment: Films & Sheets Driving Packaging Applications

Films and Sheets constitute the largest segment of the LDPE market. Their flexibility, low cost, and strong barrier properties make them highly suitable for packaging applications in the food & beverage, pharmaceutical, and personal care industries. The tubular and autoclave manufacturing methods dominate production, optimizing throughput and reducing operational costs. The surge in demand for e-commerce packaging, driven by global digital commerce growth, has further reinforced this segment’s dominance.

Fastest Growing Segment: Injection Molding Expanding Industrial Applications

Injection molding is the fastest-growing segment within the LDPE market. The rise of industrial automation and increasing demand for custom-designed LDPE parts in automotive, consumer electronics, and electrical appliances are driving market expansion. Its ability to produce high-precision, durable components at scale is attractive for industries seeking cost-effective yet high-performance materials, further accelerating LDPE adoption.

Geographical Penetration

Asia Pacific's Rapid Industrialization and Agricultural Demand

Asia Pacific (APAC) is poised to be the fastest-growing region for LDPE demand, driven by significant industrial growth, urbanization, and governmental push towards modernizing agriculture. China leads the region with massive investments in infrastructure and industrial polymers, with domestic players like Sinopec and Formosa Plastics expanding capacity. India is rapidly adopting LDPE in agriculture (films for crop protection), packaging, and construction, fueled by programs like "Make in India" and "Digital India." Southeast Asia’s expanding manufacturing base is also propelling regional growth.

India Low-Density Polyethylene (LDPE) Market Outlook

India represents one of the fastest-growing markets globally due to its expanding industrial base, significant population growth, and increased consumption of packaged goods. The agriculture sector is leveraging LDPE films for improved yield and sustainability, while packaging applications continue to expand in FMCG and pharmaceutical industries. Domestic producers and a robust network of distributors further support market momentum, while environmental regulations encourage the shift towards sustainable and recycled LDPE usage.

China Low-Density Polyethylene (LDPE) Market Trends

China dominates the APAC LDPE market, with strong policy support for polymer industry advancement. Government regulations aimed at reducing plastic waste are reshaping the competitive landscape, pushing innovation towards recyclable and environmentally-friendly LDPE products. Leading domestic producers are advancing R&D to develop green LDPE variants, catering to both local and export markets. The focus remains on applications in packaging, agriculture, and electrical insulation.

North America's Market Leadership and Technological Advancements

North America holds a significant market share in the LDPE industry, underpinned by mature industrial applications, high automation levels, and advanced recycling infrastructure. The U.S. is the largest regional contributor, driven by strong demand in packaging, agriculture, and electrical insulation applications. Technological advancements focus on enhancing material properties and process efficiencies, especially in sustainable product development. Canada contributes through innovations in green polymers and niche applications in industrial and consumer sectors.

United States Low-Density Polyethylene (LDPE) Market Insights

The United States is one of the most mature and advanced markets for LDPE, driven by its large-scale industrial base, advanced manufacturing infrastructure, and high consumer demand, particularly in the packaging and agricultural sectors. Strong demand from the food & beverage industry, as well as significant applications in flexible packaging solutions, propel market growth. Moreover, increasing regulatory focus on sustainable packaging solutions is driving innovation in biodegradable and recyclable LDPE applications. The U.S. market accounts for a significant share of the North American LDPE market, supported by the presence of key industry players and strategic manufacturing investments.

Canada Low-Density Polyethylene (LDPE) Industry Growth

Canada represents a high-growth segment of the North American LDPE market, supported by rising demand in packaging and agricultural applications, particularly in regions with a strong agricultural economy. Increasing investments in sustainable and environmentally friendly solutions, coupled with technological innovation in film applications, boost market prospects. Canadian manufacturers are focusing on enhanced product differentiation through performance-oriented LDPE grades, driven by demand from food packaging and industrial applications.

Sustainability Analysis

LDPE plays a dual role in sustainability. Positively, it enables reduced material usage and longer-lasting product lifecycles in applications such as flexible packaging and protective films. However, its environmental footprint remains a concern due to challenges in recycling and disposal. Industry leaders are investing in chemical recycling technologies, developing biodegradable formulations, and implementing closed-loop supply chains. Governments globally are enforcing stricter regulations to promote sustainable practices, influencing industry players to accelerate eco-innovation strategies and reduce lifecycle carbon emissions.

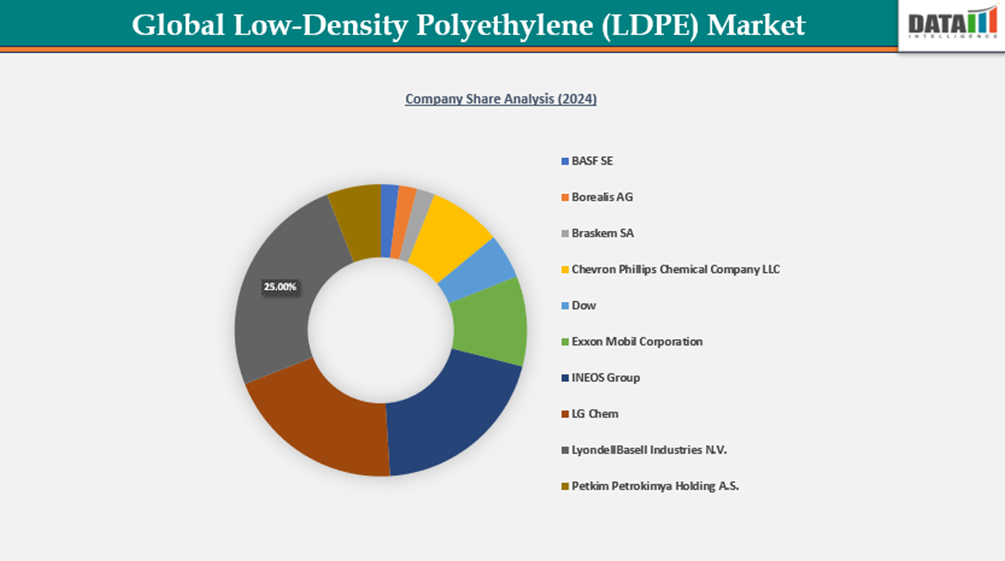

Competitive Landscape

The LDPE market is highly competitive and consolidated, driven by leading global petrochemical companies striving for economies of scale, production efficiency, and geographic market expansion.

These players benefit from extensive global production networks, large-scale R&D investments, and strong distribution channels. They focus on developing advanced LDPE grades tailored for specific end-use sectors such as flexible food packaging, industrial films, and agricultural applications.

To address growing environmental concerns, key players are innovating in bio-based LDPE variants and recyclable solutions, thereby enhancing sustainability credentials.

Strategic partnerships, capacity expansions, and technology innovation (e.g., gas-phase and tubular polymerization processes) are core strategies employed to strengthen competitive positioning.

The focus on high-performance and differentiated LDPE products helps market leaders demonstrate superior ROI for industrial and packaging customers while complying with increasingly stringent environmental regulations.

Why Choose DataM?

Data-Driven Insights: Dive into detailed analyses with granular insights such as pricing, market shares and value chain evaluations, enriched by interviews with industry leaders and disruptors.

Post-Purchase Support and Expert Analyst Consultations: As a valued client, gain direct access to our expert analysts for personalized advice and strategic guidance, tailored to your specific needs and challenges.

White Papers and Case Studies: Benefit quarterly from our in-depth studies related to your purchased titles, tailored to refine your operational and marketing strategies for maximum impact.

Annual Updates on Purchased Reports: As an existing customer, enjoy the privilege of annual updates to your reports, ensuring you stay abreast of the latest market insights and technological advancements. Terms and conditions apply.

Specialized Focus on Emerging Markets: DataM differentiates itself by delivering in-depth, specialized insights specifically for emerging markets, rather than offering generalized geographic overviews. This approach equips our clients with a nuanced understanding and actionable intelligence that are essential for navigating and succeeding in high-growth regions.

Value of DataM Reports: Our reports offer specialized insights tailored to the latest trends and specific business inquiries. This personalized approach provides a deeper, strategic perspective, ensuring you receive the precise information necessary to make informed decisions. These insights complement and go beyond what is typically available in generic databases.

Target Audience 2024

Manufacturers/ Buyers

Industry Investors/Investment Bankers

Research Professionals

Emerging Companies

Suggestions for Related Report