Barrier Resins Market Size

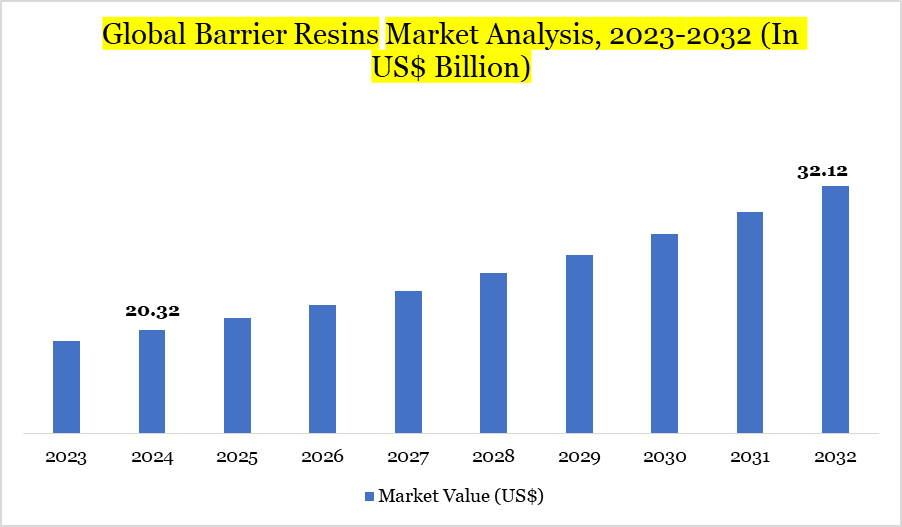

Barrier Resins Market size reached US$ 20.32 billion in 2024 and is expected to reach US$ 32.12 billion by 2032, growing with a CAGR of 5.89% during the forecast period 2025-2032.

Barrier resins have become essential elements in contemporary packaging, providing strong defense against oxygen, moisture, mist, and chemical penetration. These materials encompassing synthetic variants such as Polyvinylidene Chloride (PVDC), Ethylene Vinyl Alcohol (EVOH), and Polyethylene Naphthalate (PEN), as well as bio-based alternatives are widely utilized in the food and beverage, pharmaceutical, cosmetics, and agriculture sectors.

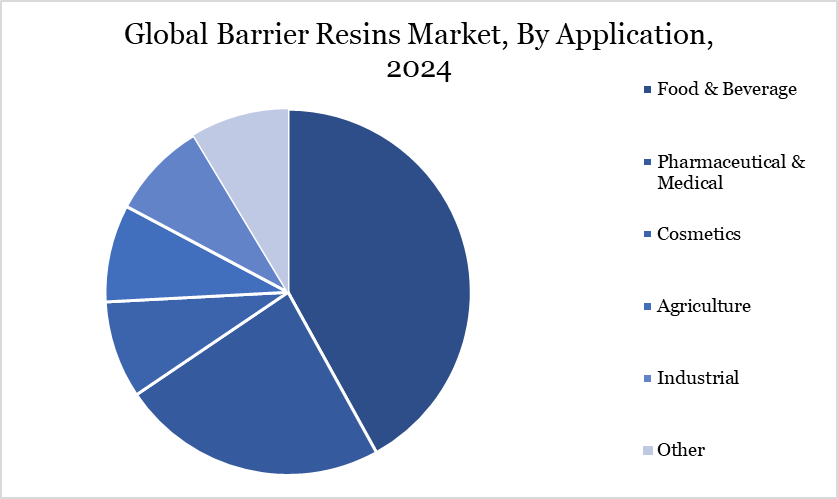

Barrier resins enhance cost-effectiveness, reduce weight, and improve shelf life by substituting heavy packaging materials such as glass and metal, especially in products like canned milk, meats, carbonated beverages, and medications. Significantly, the food and beverage sector constitute the largest end-use category, propelled by an increasing customer inclination towards fresh, securely packaged items.

Technological advancements, along with strategic innovations like Ashland's October 2023 introduction of a low-density polyethylene (LDPE) resin for flexible packaging, are driving market expansion. The increasing need for tamper-proof pharmaceutical packaging and sustainable materials is transforming the competitive environment and expediting the global utilization of barrier resins.

Barrier Resins Market Trend

The barrier resin market is experiencing a transition driven by sustainability demands and changing consumption trends. The rise of e-commerce and online grocery shopping has increased the demand for lightweight, resilient packaging that can endure long-distance transportation while maintaining product freshness and integrity. As customers increasingly pursue minimally processed and health-oriented food options, manufacturers are adopting advanced barrier technologies such as EVOH and PET to prolong shelf life.

Innovations are increasingly favoring sustainable alternatives, such bio-based polylactic acid (PLA), polyhydroxyalkanoates (PHA), and Coca-Cola’s PlantBottle, in accordance with circular economy objectives. Furthermore, organic and plant-derived resins produced from renewable resources like sugarcane and castor oil are increasingly popular, however they face obstacles due to elevated production costs and restricted scalability.

In January 2024, Dow Chemical's sustainable polyurethane effort demonstrated the industry's transition toward circular feedstocks. These continual developments signify a distinct market trend: the transition towards sustainable, functional, and versatile packaging solutions.

For more details on this report – Request for Sample

Market Scope

| Metrics | Details |

| By Resin Type | Polyethylene Naphthalate (PEN), Polyvinylidene Chloride (PVDC), Ethylene Vinyl Alcohol Copolymer (EVOH), Biobased Barrier Resins, Others |

| By Packaging Type | Flexible packaging, Rigid packaging |

| By End-user | Food & Beverage, Pharmaceutical & Medical, Cosmetics, Agriculture, Industrial, Other |

| By Region | North America, South America, Europe, Asia-Pacific, Middle East and Africa |

| Report Insights Covered | Competitive Landscape Analysis, Company Profile Analysis, Market Size, Share, Growth |

Barrier Resins Market Dynamics

Superior Packaging Solutions for Pharmaceuticals and Food Safety

A primary driver for the expansion of the barrier resin market is the increasing need for high-performance packaging in the pharmaceutical and food industries. Advanced production processes have facilitated the creation of specific barrier resins that safeguard medications from oxygen, UV light, moisture, and contamination, ensuring prolonged shelf life and therapeutic effectiveness.

Typical applications encompass push-through blister packs, bottle labels, and sterile pouches fabricated from PVDC and EVOH resins. The food and beverage sector are concurrently witnessing an escalating demand for packaging that preserves flavor, texture, and nutritional integrity in products like meat, dairy, canned fruits, and carbonated drinks.

Substituting conventional materials such as cans and glass with moldable, lightweight barrier films enhances operational efficiency and consumer convenience. As global health awareness rises and middle-class populations grow in developing countries like India and China, manufacturers are utilizing barrier resins to fulfill demands for safety, hygiene, and durability, establishing this segment as a fundamental aspect of market growth.

Fluctuations in Raw Material Prices and Complications in Recycling Inhibit Growth

The barrier resin industry encounters considerable limitations, chiefly attributable to fluctuating raw material costs and environmental issues. Essential inputs such as crude oil, natural gas, and monoethylene glycol (MEG) are influenced by worldwide price volatility. The US Energy Information Administration indicated a decline in average natural gas prices from US$ 2.82 per million Btu in 2019 to US$ 2.22 in recent years. This fluctuation negatively affects manufacturing expenses and profitability.

The majority of synthetic barrier resins are non-biodegradable and release greenhouse gases during production, presenting environmental issues. The recycling of multilayer packaging, typically made from various resin types, necessitates sophisticated separation methods that are not widely available, leading to challenges in adhering to new global waste management rules.

Despite the availability of alternatives such as PLA and water-based resins, their durability generally falls short of that of conventional materials, hindering their widespread adoption. These combined characteristics create significant obstacles to continuous industry growth, particularly in areas with stringent regulatory regimes.

Barrier Resins Market Segment Analysis

The global barrier resins market is segmented based on resin type, packaging type, application and region.

Smart Packaging Starts with Barrier Resins in the Food & Beverage Industry

In the food and beverage industry, barrier resins play an essential role across several end-user segments by guaranteeing product durability, safety, and transportability. Principal applications encompass packaging for meat, fish, dairy products, canned vegetables and fruits, carbonated beverages, beer, wine, and prepared meals. Manufacturers utilize barrier films to inhibit the ingress of oxygen and odors, thereby safeguarding flavor, nutrition, and sensory characteristics.

Canned goods and perishable items employ PVDC and EVOH resins to prolong shelf life and minimize spoiling. Producers of carbonated beverages want lightweight resin-based bottles to improve transport efficiency and minimize emissions. The moldable characteristics of barrier resins enhance dairy and canned milk packaging options, enabling customized designs and improved handling efficiency.

As consumer health awareness rises and the demand for sustainable solutions increases, food firms are progressively incorporating organic barrier resins, such as PLA. This transition signifies the industry's focus on sustainability, quality maintenance, and adherence to regulations.

Barrier Resins Market Geographical Share

Europe Advocates Sustainable Packaging through Regulatory Endorsement

Europe is a crucial location in the global barrier resin market, propelled by rigorous environmental regulations and ambitious circular economy initiatives. Germany, France, and the UK are leading in the adoption of recyclable and environmentally sustainable packaging materials. Germany, specifically, advantages from a sophisticated manufacturing industry and strong demand from the food, pharmaceutical, and cosmetics industries.

The enforcement of prohibitions on single-use plastics and adherence to EU waste reduction objectives has stimulated innovation in sustainable barrier solutions. Regulatory authorities are advocating for adherence to packaging waste directives, encouraging producers to utilize recyclable and bio-based polymers.

Europe has established itself as a market leader and innovation engine because to the presence of mature end-user sectors and a sustainability-focused consumer base. The area is experiencing sustained growth in demand for high-performance, lightweight, and eco-friendly barrier resin solutions across various applications.

Barrier Resins Market Major Players

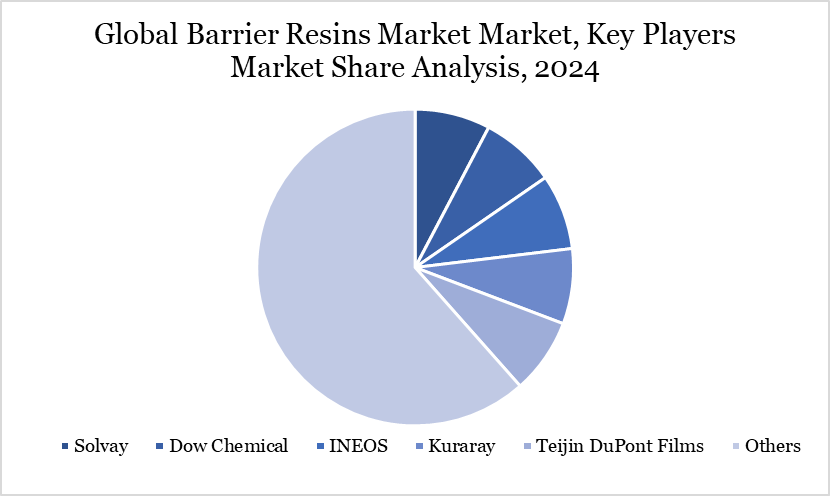

The major global players in the market include Solvay, Dow Chemical, INEOS, Kuraray, Teijin DuPont Films, Asahi Kasei, Ashland Global Holdings Inc., Invista, Kureha Corporation, LG Chem.

Sustainability Analysis

Sustainability has emerged as a critical determinant in the progression of the barrier resins industry. Traditional synthetic resins, mainly sourced from fossil fuels, contribute to greenhouse gas emissions and pose waste disposal difficulties; nevertheless, the industry is actively transitioning to eco-friendly alternatives. Bio-based and plant-derived resins, generated from sugarcane, corn, soybeans, and castor oil, provide renewable, low-toxicity alternatives with diminished environmental impacts.

Bio-based epoxy and water-based resins significantly release reduced levels of volatile organic compounds (VOCs) and are increasingly used in packaging and adhesives. UV-curable resins facilitate low-emission, rapid-cure applications in industrial environments. Nonetheless, constraints persist, such as diminished durability in certain bio-resins and technological obstacles in the recycling of multi-layer films.

With increasing regulatory scrutiny and a movement in customer demand towards sustainable packaging, firms are investigating scalable, low-impact alternatives. Initiatives such as Dow Chemical’s 2024 mass-balance polyurethane initiative highlight a wider industry dedication to incorporating circular feedstocks and diminishing dependence on virgin fossil resources.

Key Developments

In August 2024, 5,000 tons/year of production capacity was added to US and European operations, with an additional 5,000 tons/year planned for 2026. This expansion aims to meet the growing demand for EVOH resin, particularly in Asia, where the food packaging market is rapidly expanding.

In November 2023, INEOS Styrolution Group finalized the acquisition of BASF's global styrene business, establishing itself as a significant contender in the polystyrene (PS) industry, which is employed in barrier resin blends.

Why Choose DataM?

Data-Driven Insights: Dive into detailed analyses with granular insights such as pricing, market shares and value chain evaluations, enriched by interviews with industry leaders and disruptors.

Post-Purchase Support and Expert Analyst Consultations: As a valued client, gain direct access to our expert analysts for personalized advice and strategic guidance, tailored to your specific needs and challenges.

White Papers and Case Studies: Benefit quarterly from our in-depth studies related to your purchased titles, tailored to refine your operational and marketing strategies for maximum impact.

Annual Updates on Purchased Reports: As an existing customer, enjoy the privilege of annual updates to your reports, ensuring you stay abreast of the latest market insights and technological advancements. Terms and conditions apply.

Specialized Focus on Emerging Markets: DataM differentiates itself by delivering in-depth, specialized insights specifically for emerging markets, rather than offering generalized geographic overviews. This approach equips our clients with a nuanced understanding and actionable intelligence that are essential for navigating and succeeding in high-growth regions.

Value of DataM Reports: Our reports offer specialized insights tailored to the latest trends and specific business inquiries. This personalized approach provides a deeper, strategic perspective, ensuring you receive the precise information necessary to make informed decisions. These insights complement and go beyond what is typically available in generic databases.

Target Audience 2024

Manufacturers/ Buyers

Industry Investors/Investment Bankers

Research Professionals

Emerging Companies